An easy way to improve your welding on heavy-gauge material.

Applications that would find ceramic weld backing advantageous include structural steel fabrication, pressure vessel manufacture, shipbuilding and pipeline seam welding.

Here are 7 reasons you could benefit from using ceramic weld backing:

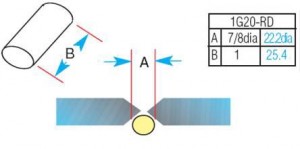

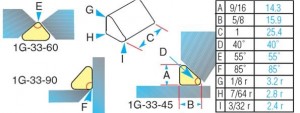

- Get x-ray quality back beads on root pass.

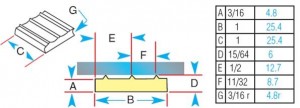

- Wider heat receptive pressure sensitive foil for improved adhesion.

- Eradicates the need for gouging and grinding as welding can be carried out from a single side with full penetration.

- Thus eliminating the risk of timely re-work and costly rejects.

- Allows the use of increased welding currents as the ceramics tiles support the active weld pool.

- Weld pool support provided by the backing also allows for increased welding speeds, decreasing arc energy and subsequently Heat Affected Zone.

- As the root area is fully enclosed, oxidation of the weld surface is reduced, eliminating the need for post-weld cleaning.

We can offer Katback ceramic weld backing from Gullco, world leaders in welding and cutting automation products. Weld backing can be sent worldwide, for more information click here.

comments

Pingback: 34 Tips to Weld with Ceramic Backing - Welding Mastermind

Pingback: 34 Tips to Weld with Ceramic Backing – Welding Mastermind