For over 50 years, we have supplied refurbished Welding and Cutting machinery to the World

Not everyone can afford a brand new machine which is why for many, many years we have concentrated on refurbishing machinery.

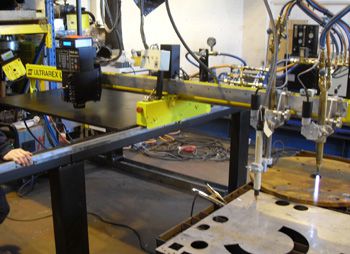

Bespoke, refurbished fabrication equipment to the highest standard can be found along side our used and new products. Click the links see the massive range of Welding products, CNC Cutting Machines, Positioning machinery and top brands in stock at discounted prices. Available today for UK or Export Sales.

Find out below how you can give your own plant and equipment a facelift and bring it up to date and improve efficiency.

Discuss your refurbishment

+44 (0)116 269 6941

Refurbishment Process

1. Quick check to ensure the machine works.

2. Take off any electrical components for repair or replacement

3. Dismantle ready for stripping paintwork back to the original metal base

4. Remove any sub assemblies or wear parts for evaluation. (Bearings, hoses, piping, seals, brake coils, timing belts, oil, Contactors, Gas valves)

4. Prepare the surface for primer coat. Prime and re-spray in customer's RAL colour choice. Textured paint can also be chosen.

5. Assemble and re-fit new / refurbished parts / assemblies. (electrical controls, displays, hoses, piping, bearings, seal, pcbs, switches, guards)

6. Qualified Engineers to apply power / load test / weld test or function test as required .

7. Photos and videos prepared for customer approval prior to despatch.

Qualified Engineers

We have British trained and qualified Engineers who supervise the whole refurb process and adhere to very high standards of workmanship. With our extensive knowledge of all types of brands and models of welding machinery, plus our huge range of spares and parts, we are able to refurbish the majority of equipment that we supply.

As our used welding plant varies, the refurbishment process time of each machine does too.

A welding positioner and CNC plasma cutter can take approximately 2 weeks to be completed, this is a very short time compared to waiting for a new machine to be delivered.

We can often offer you a Loan machine whilst your own is refurbished to save on production down time.

Each machine will have a minimum of 4 months Parts and Labour warranty and any new parts or electrical components will have 12 months warranty as standard.

Remember...

We do not JUST sell machinery...

We take pride in supplying first class quality equipment to the medium / heavy welding and fabrication industry around the World.

Many of our clients send what appears to be a "graveyard" machine into us as they do not have the capital funds to invest in buying another machine. We are able to save them money, by fully refurbishing their own equipment.

Do you have machinery lying idle or in need of some TLC? Surely it would be worth investing to make this machine work for you again? Let us refurbish your industrial welders for you. Your machine will have warranty period and any new parts or electrical components will have 12 months warranty as standard.