For this post we welcome Josh Maynard of anonymousfab.com, he has a great blog and online welding community and has given us his five top tips for welding aluminium.

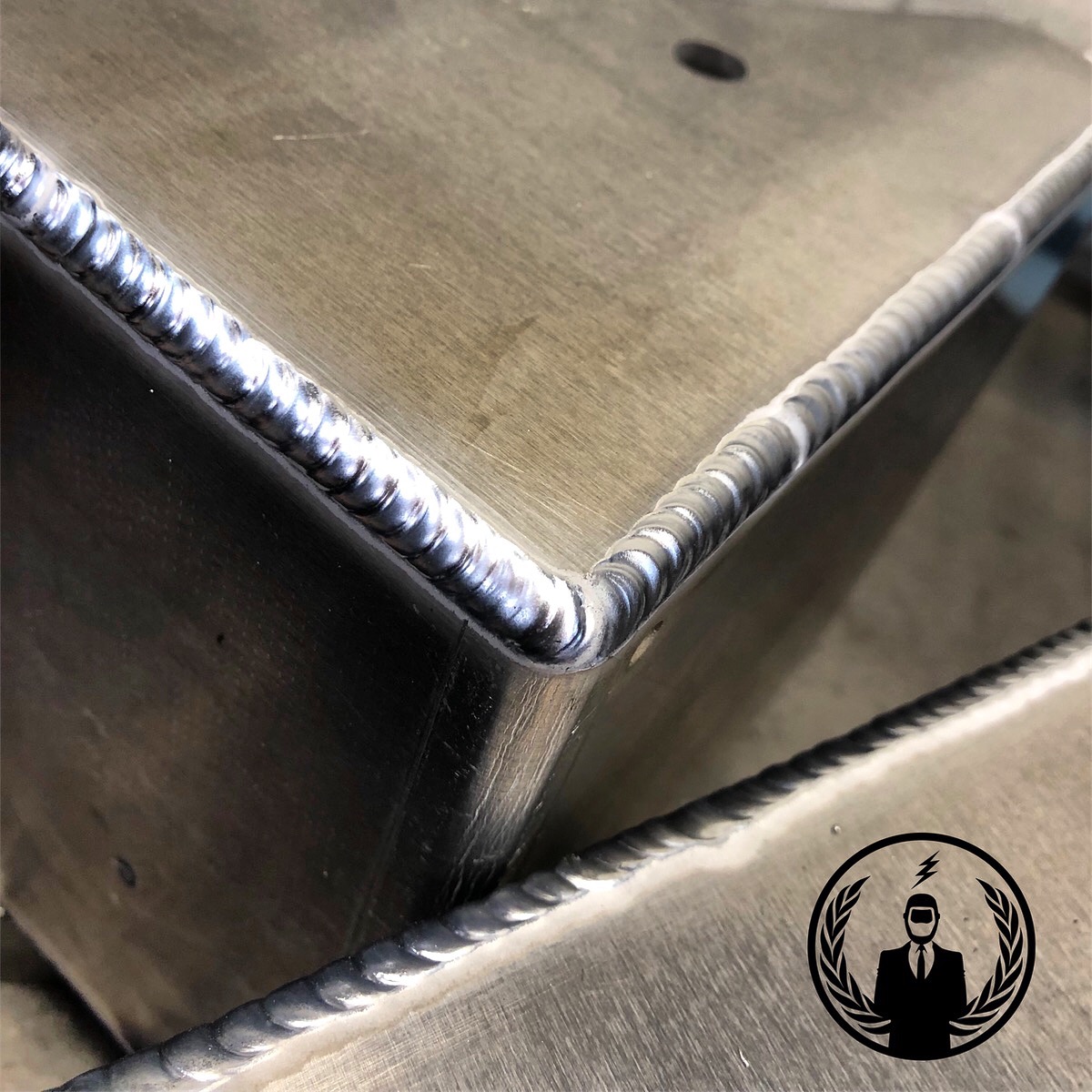

Aluminium is my FAVOURITE metal to weld with the TIG or Tungsten Inert Gas process. Although I love it now, at first it was difficult for me to control the weld puddle and even lay down something that looked like a weld. Below I’ll give you 5 quick tips that should help you weld Aluminum.

Quick Aluminum Welding Tips

– Understand Your Metal

– Copper Wire Brush

– Clean, Clean, Clean

– Torch Angle is Key

– Practice

1. Understand Your Metal

Aluminium has high thermal conductivity properties which means the heat is going to want to spread throughout the material. Unlike steel, when TIG welding on aluminium, keep in mind your travel speed can be faster.

Aluminium is a porous metal with a melting point of 1,221 F.

Aluminium is the most abundant metal on earth but does not occur as a metallic form in nature, instead it’s an ore known as Bauxite.

2. Wire Brush

Wire Brush material with copper or brass wire brush. This will help break up and remove the oxide layer (do not use a steel wire brush as the steel will contaminate the aluminium).

Copper Wire Brushes work great to break up the oxide layer.

When brushing your aluminium you will notice the metal starts to dull. This is a good sign that you have broken up some of the oxide layers.

Keep in mind that I have also had good results with one direction brushing as opposed to forward and backward brushing, so give this a go.

3. Clean Metal

Wipe down base material and filler rod with denatured alcohol or acetone. Aluminium is extremely sensitive to impurities, so clean your filler rods even if they are brand new.

Setting up is crucial for proper aluminium welds – be sure your machine settings such as gas flow, cup sizes etc. are correct for your application.

If you are working on a steel surface while welding aluminium, it’s important to have a clean and smooth table without any metal shavings. Metal shavings can arc your aluminium and cause burnt marks.

4.Torch Angle Is Key

Torch angle is important because your filer rod will want to ball up before you can even dip so make sure you feed your aluminium filler rod fast. Also, be sure your TIG welding torch angle remains 90 degrees or as close to vertical as possible.

Certain applications will allow for a slight tilt in your welding torch angle but it’s never much for aluminium.

5.Practice!

As obvious as this sounds it can’t be more true. I got good at welding aluminium by getting a production welding job that required 80% Aluminum TIG welding. I’m constantly tweaking with frequency, cleaning action, cups, tungsten and new techniques. One technique I found very helpful when welding aluminium is to watch the puddle, not your tungsten!

This all may seem overwhelming at first but my recommendation to you is to change one thing at a time, take some deep breaths of fresh air when you get frustrated, and just keep welding!

Now your knowledge is up to speed, make sure your welding machine is too! We have a large range of new and used or refurbished AC/DC TIG welding machines for aluminium welding applications, take a look at our current stock here or alternatively if you are thinking about selling your machine, speak to Peter and Bev for a fair and easy deal!

comments

Great tips for aluminum welding! Cleaning the metal properly and using the right wire brush really makes a difference. I also love the reminder to focus on the puddle instead of the tungsten—such a helpful technique! Practice really does make perfect with aluminum, and these tips will definitely help anyone looking to improve their skills. Thanks for sharing!

Thank you. As Santhana Lakshmi Metals are a manufacturer and trader of aluminium and metals, your comments are valuable to our readers.

Thanks so much it helpful