Two Metals Enter, One Leaves!

This is a relatively new method of welding in the automotive industry but already established and used widely in the aerospace sector.

History.

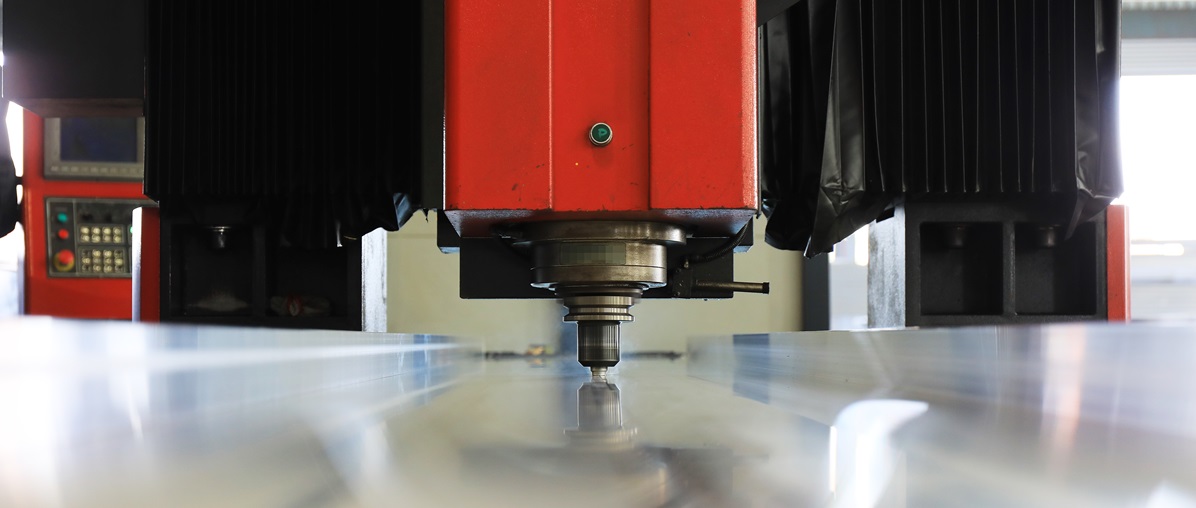

The typical images of welding—a robotic arm burping sparks or a masked Jesse James hovering over a glowing metal puddle—don’t apply to friction stir welding (FSW).

The metal-joining technique was developed in 1991 by The Welding Institute, an industrial research center here in Cambridge, England.

In the mid-1990s, two Scandinavian aluminium extrusion companies became the first to use the technique commercially. Since then, it has been widely adopted by the aerospace industry and has slowly trickled into the automotive realm.

Sparks and eye shields are part of fusion welding, where an electric current heats two pieces of metal to a molten state. When the metal pool cools, a single, solid joint results. In contrast, FSW is a solid-state weld involving no molten metal. Heat generated by pressure and friction is all that’s needed to ensure a strong metal bond.

The benefits are numerous. Most notably, FSW works with dissimilar metals. Not only can it weld different aluminum alloys, but it can also weld steel to aluminum. Before FSW, this was time consuming, costly, and often resulted in brittle bonds not suitable for load-bearing applications.

Mazda, for example, uses FSW to attach steel studs to the MX-5 Miata’s aluminum inner-trunk panel. And the new Honda Accord’s front subframe, which carries the engine and some suspension components, is made of aluminum and steel halves. The details are proprietary, although Honda has said this is the first use of continuous, or linear, FSW in a bi-metal structural component of a production vehicle. The two halves overlap, and the welds are located between the two components. A barrier placed between the steel and aluminum diminishes the likelihood of bi-metallic corrosion. Honda says a new iron-aluminum chemical compound–Fe4A113–forms during its FSW process, and that the bond is as strong as a conventional weld.

Benefits.

FSW also has gained traction with automakers for its ability to spot-weld thin aluminum sheets, such as the aforementioned MX-5’s trunk panel. Fusion-welding thin-gauge aluminum can perforate it, but because of the relatively low heat associated with FSW, deformations are less likely. Also, compared with fusion welding, FSW can cut electricity consumption in half.

And unlike conventional welding, which adds mass in the form of filler metal from welding wire, FSW adds nothing. So it reduces the weight of the finished product at a time when every ounce counts in today’s fuel-economy-driven industry. Given this, and the ability to weld dissimilar metals, friction stir welding opens up more opportunities to use aluminum to trim weight. Expect to start seeing FSW everywhere in the automotive sphere.

Applications.

Friction Stir Welding is ideal for joining straight profiles and flat plates with a thickness of 1.2-25 mm. When welding materials with a thickness of more than 15 mm, the welding is done from both sides. The maximum thickness is around 60 mm at 100% penetration.

Suitable application areas:

- Shipbuilding

- Offshore platforms

- Aerospace industry

- Railway wagons, trams, underground train carriages

- Automotive industry

- Production of electric motors

- Defence industry

- Cooling elements

- Basically all aluminium, copper and magnesium alloys can be friction stir welded with high quality and speed.

As ESAB agents, we are able to supply ESAB Friction Stir Welding equipment.

Look at the ESAB Legio and programme software SuperStir

Apple already use this process to create the new iMacs!

Think light weight – think FSW!

It will be used more and more in the coming years. I found this article and images on the Car and Driver web site.