Are you producing components that need to be precisely welded?

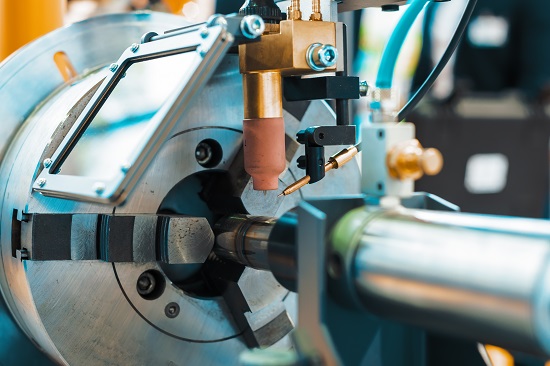

A lathe type welding system could be the answer for you.

Using either welding positioners or pipe rotators/turning rolls, these welding systems can fully automate your welding process.

The set up in the video was sold as a package for TIG welding of stainless steel, however systems are bespoke and can be used with GTAW/TIG, GMAW/MIG and PAW/plasma arc welding.

It is ideal for producing items such as exhausts, flues, small pressure vessels and conveyor rollers using the circumferential welding process.

There is a wide choice of components available, offering great flexibility to produce a custom built system to meet each clients requirements.

Basic packages include base rails, mounting rails, column tube and end brackets, with additional options of pneumatic torch lift, sequencers and chucks.

The special capability of this system will help you produce high quality circumferential welds, and provide the advantage of fast pay-back, safety, and less worker fatigue, which will exactly meet your needs.

Click here or contact us to automate your welding process today!