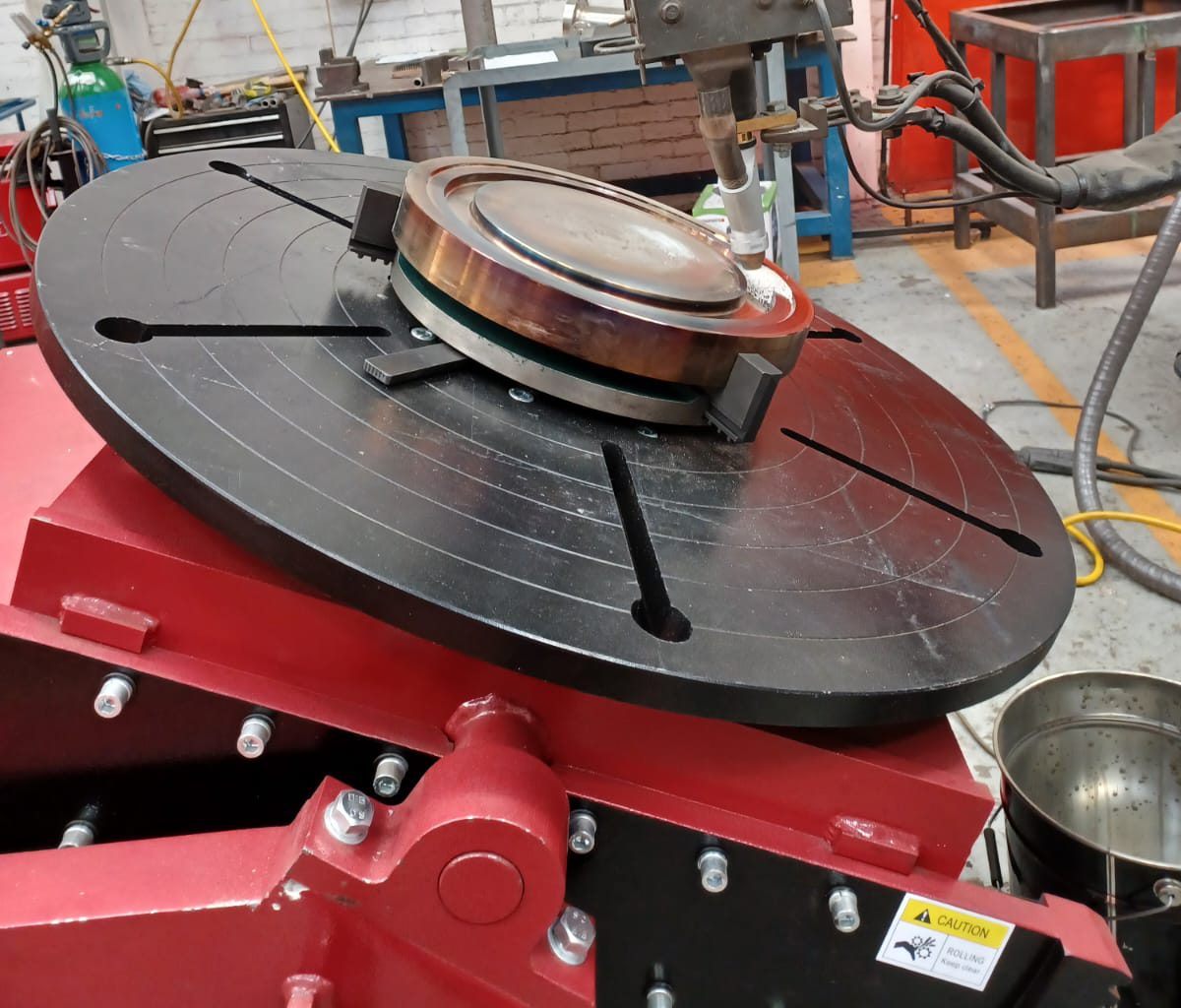

Positioners are beneficial for welders: they add ergonomic working comfort and ensure a safer working environment.

Additionally, using a positioner increases welding productivity by as much as 70% providing the quickest means of both rotating and tilting through 360 degrees while allowing maximum access to the workpiece.

The fact that work-pieces can be adjusted to the best possible down hand welding positions makes this achievable.

The fact that work-pieces can be adjusted to the best possible down hand welding positions makes this achievable.

Typical applications for heavy-duty positioners

- Automated welding of heavy thick-walled dish ends

- Cladding of pressure vessel components

- Narrow gap and tandem narrow gap welding stations of thick-walled pressure vessels

- Foundations for wind energy plants

- Propeller housings, winches, and other shipbuilding and offshore industry components

What is involved in the welding process

The welding process involves a sequence of operations which includes presenting the workpiece to the welding device (or vice versa), creating relative motion between the workpiece and the welding device, controlling the welding process, eg speed, direction, current, etc, and re-positioning the workpiece for the next weld.

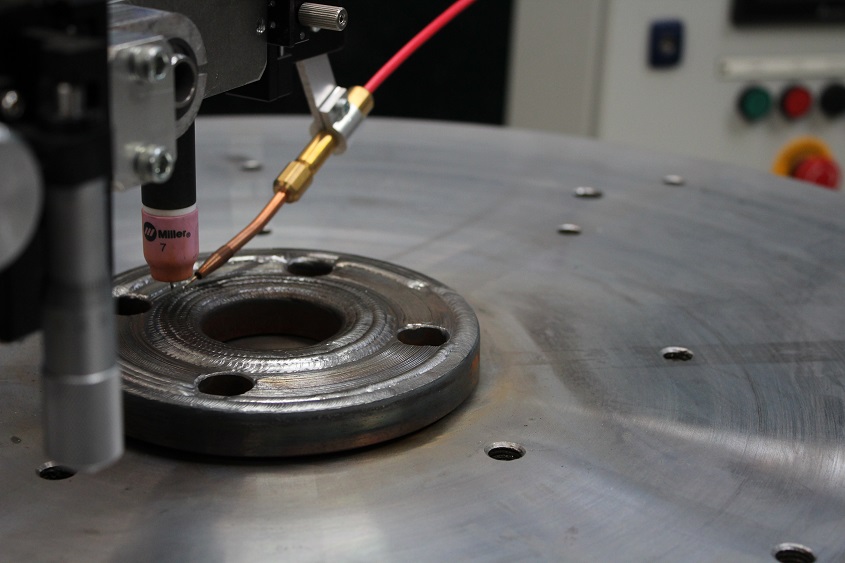

Automated welding is defined as automatically controlling the relative movement between the welding head and workpiece. Automatic welding is used with variety of welding process including metal inert gas (MIG), tungsten inert gas (TIG) and submerged arc welding (SAW).

The main benefits attributed to automated welding are improved economy derived from faster cycle times and consistent quality due to reduced level of weld defects from a more precise control of the welding process.

On the down side, welding geometry tends to be restricted to simple straight lines, and setting time is increased.

Need help to decide the most suitable positioning equipment for your job? Want to add comfort to your welder whilst improving productivity?

Welding positioners, turntables and head & tails stocks come in many different sizes and carrying capacities. We stock the whole range.

Get in touch with us or view the welding positioners we buy and sell

Read our resources pages for more information on brands and types of positioning machinery if you are looking to automate your workshop

comments

welding positioners enhance productivity by up to 70% by providing ergonomic comfort and enabling precise 360-degree rotation and tilting of workpieces. They are crucial for heavy-duty applications like automated welding of thick-walled components and shipbuilding. Positioners improve welding efficiency and quality through better control and faster cycle times, though they may limit welding geometry and increase setup time.

welding positioners can boost productivity by up to 70% by allowing precise rotation and tilting of workpieces, which enhances ergonomic comfort and safety. They are ideal for applications such as automated welding of heavy-duty components and pressure vessels. Positioners improve welding efficiency through better access, consistent positioning, and faster cycle times, though they may increase setup time and limit welding geometry to simpler shapes.