The construction of bulk storage tanks can be a slow process, heavy on man hours and an awkward job.

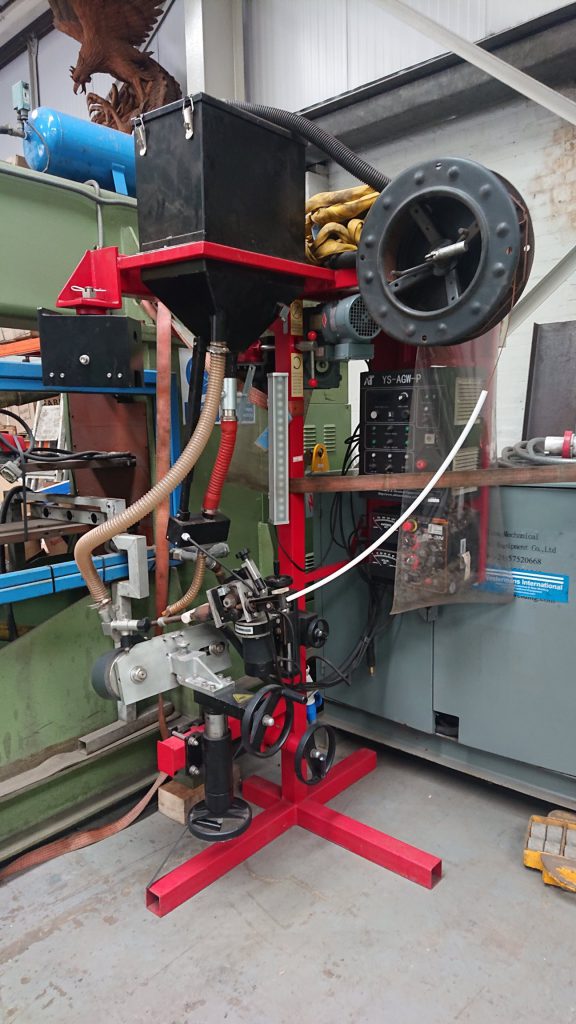

Revolutionise your vessel welding applications with these automatic girth welders from Koike.

Designed for welding seams on tanks for storing LNG, oil, flour and grain etc., they are an extremely versatile piece of kit. Capable of both internal and external welds.

Effectively cutting down on manual welding time and increasing site safety, field erected storage tanks of any diameter can be welded efficiently and safely with these girth welding machines.

Product features:

- Model Koike AGW-I/P

- Adjustable frame handles plates from six to 10 feet high

- Plates up to 2″ thick

- Operating speeds from 4 – 105 inches per minute

- Cuts in-field welding time by up to 40%

- Fitted with Lincoln Electric DC 1000 amp power source and NA3 submerged arc welding head

- Complete with flux recovery

- As new condition with 6 month warranty package

- Also available for short or long term UK based hire

The Koike AGW automatic girth welding system is made for applications in the oil field sector, tank fabrication, nuclear power plants and waste management facilities.

Uses include boiler manufacture, chemical mixing tanks, oil storage, water storage and treatment, tankers and reactors.

For more examples of submerged arc welding equipment, take a look at our YouTube playlist.

All of our equipment is available for export with warranty around the world.

We handle logistics and documentation for both domestic and International sales, in the EU and Worldwide.

Equipment is available for viewing at our works in Leicestershire, or contact Craig Westerman, Sales Director to discuss further and find out how you can benefit from these automatic submerged arc welding packages.