Corimpex Automatic SubArc Welder for Plate Girders and Welded Beams

This equipment is available for delivery to United States

This equipment is available for delivery to United States

- This Corimpex Submerged Arc beam welding manipulator ideal for structural steel contractors and manufacturers of steel girders and beams who want to invest in the automatic sub-arc welding process

- Applications. Steel Fabrication, Steel Bridges, Lighting, Telecommunication and Transmission, Shipyard Offshore & Onshore Platforms Transport, Wind Towers, Oil & Gas, Pressure Vessels & Petrochemicals

- This package for steel fabrication of beams and girders would take you from manual to welding automation

- Welded Plate Girders - H Beams - I Beams - Flanges - Steel Structures - Support Trusses - Building Framework - Beam Fabrication

- The manufacturer is Corimpex, an Italian company recognised as a world leader in the engineering, production, and installation of solutions for arc welding automation.

- Their core expertise lies in the automation of submerged arc welding (SAW) processes.

- Fitted with welding equipment consisting of 2 x Lincoln Electric DC 1000 amp welding power sources with dual Lincoln Electric subarc NA3 control with seam tracking

- Removed by ourselves in full working order from a local UK business. We can give support and arrange full installation world wide

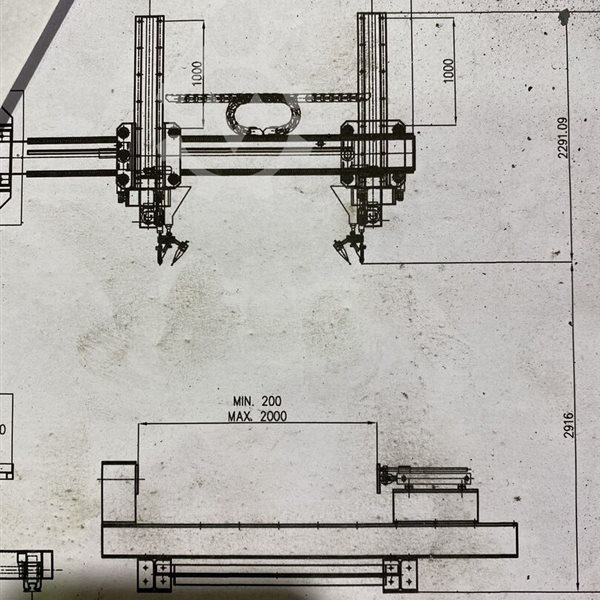

- CB-HH-2C 4 x 3 based on the following components:

- Medium duty steel fabricated column with a manual slewing ring provided with Raising and Lowering saddle powered by braked motor-gear chain/pinion drive.

- Submerged Arc Welding (SAW): SAW is a wire arc welding process that utilizes welding flux. The flux is deposited along the welding line to achieve high-quality welds.

- Maximum height of the column from the floor : 4200 mm - Maximum height under the boom : 3000 mm

- The slewing ring is bolted in a steel bolted in a steel basement provided of 4 wheels for the longitudinal travel.

- The traversing on the rails is realized by an variable speed AC motor – gear with Taco-generator to ensure a constant speed even at low revolution of the motor.

- BWM-TC - Beam Welding Machine - Welded Plate Girders - H Beams I Beams Flanges Steel Structures Support Trusses Building Framework Beam Fabrication

Lead Times

All used machines are serviced/refurbished to order, and lead times are dependant on current workload and machine type. The below can be used as a guide only, and is subject to change. If you have a deadline you need the equipment by, please contact us prior to ordering. We will always do what we can to try and work with your timescales where possible.

- “As Is” machines: 2-3 working days.

- “Serviced” machines: 7 working days.

- “Refurbished” machines: 2-3 weeks.

- “New” machines: subject to stock and supplier lead times where applicable.

Shipping

All shipping costs include packing.

UK*

- Parcel delivery: from £15 next day courier

- Pallet delivery: from £75

- Large item delivery: TBC by quotation

Northern Ireland

- Pallet delivery: £120

- Parcel and large item delivery: TBC on quotation

Ireland

- Pallet delivery: £220

- Parcel and large item delivery: TBC by quotation

Europe and Overseas

All welding equipment and machinery is sold and supplied Ex-Works, unless otherwise stated. We can however provide full freight forwarding facilities via road, sea or air freight. We work with our reliable shipping partners for one off items, up to the loading of 40ft containers. For a quotation, please contact us with your destination address/port, along with any other specific documentation requirements.

* Rates for mainland UK, subject to change. If in doubt, please send us your delivery postcode for confirmation

-600-600-c.jpg)

%20(1)-600-600-c.jpg)

-600-600-c.jpg)

-600-600-c.jpg)